The Floppy-Disk Archiving Machine, Mark III

"I'm not building a Mark III."

Famous last words.

I made the mistake of asking my parents if they had any 3.5" floppy disks at their place.

They did.

And a couple hundred of them were even mine.

Faced with the prospect of processing another 500-odd disks, I realized the Mark III was worth doing. So I made a few enhancements for the Floppy Machine Mark III:

- Changed the gearing of the track motor assembly to increase torque and added plates to keep its structure from spreading apart. The latter had been causing the push rod mechanism to bind up and block the motor, even at 100% power.

- Removed the 1x4 technic bricks from the end of the tractor tread, and lengthened the tread by several links and added to the top of the structure under those links. This reduced the frequency that something got caught on the structure and caused a problem.

- Extended the drive's shell's lower half by replacing the 1x6 technic bricks with 1x10 technic bricks; and a 1x4 plate on the underside flush with the end. This made the machine more resilient to the drive getting dropped too quickly.

- Added 1x2 bricks to lock the axles into place for the drive shell's pivot point, since they seemed to be working their way out very slowly.

- Added 1x16 technic bricks to the bottom of all the legs, and panels to accommodate that, increasing the machine's height by 5" and making it easier to pull disks out of the GOOD and BAD bins.

- Added doors at the bottom of the trays in the front to keep disks from bouncing out

- Added back wall at bottom of the trays in the back to keep disks from bouncing out.

- Moved the ultrasonic sensor lower in an attempt to reduce the false empty magazine scenario. This particular issue was sporadic enough that the effectiveness of the change is hard to determine. I only had one false-empty magazine event after this change.

- Added a touch sensor to detect when the push rod has been fully retracted in order to protect the motor. Before this, the machine identified the position of the push rod by driving the push rod to the extreme right until the motor blocked. This seems to have had a negative effect upon the motor in question. Turning the rotor of that poor, abused motor in one direction has a very rough feel. This also used the last sensor port on the NXT. (One ultrasonic sensor and three touch sensors.)

- Replaced the cable to the push rod motor with a longer one from HiTechnic.

- Significantly modified the controlling software to calibrate locations of the motors in ways that did not require driving a motor to a blocked state.

- Enhanced the controlling software to allow choosing what events warranted marking a disk as bad and which didn't.

- Enhanced the data recovery software to allow bailing on the first error detected. This helps when you want to do an initial pass through the disks to get all the good disks archived first. Then you can run the disks through a second time, spending more time recovering the data off the disks.

- Enhanced the controlling software to detect common physical complications and take action to correct it, such as making additional attempts to eject a disk.

With those changes, the Mark III wound up much more rainbow-warrior than the Mark II:

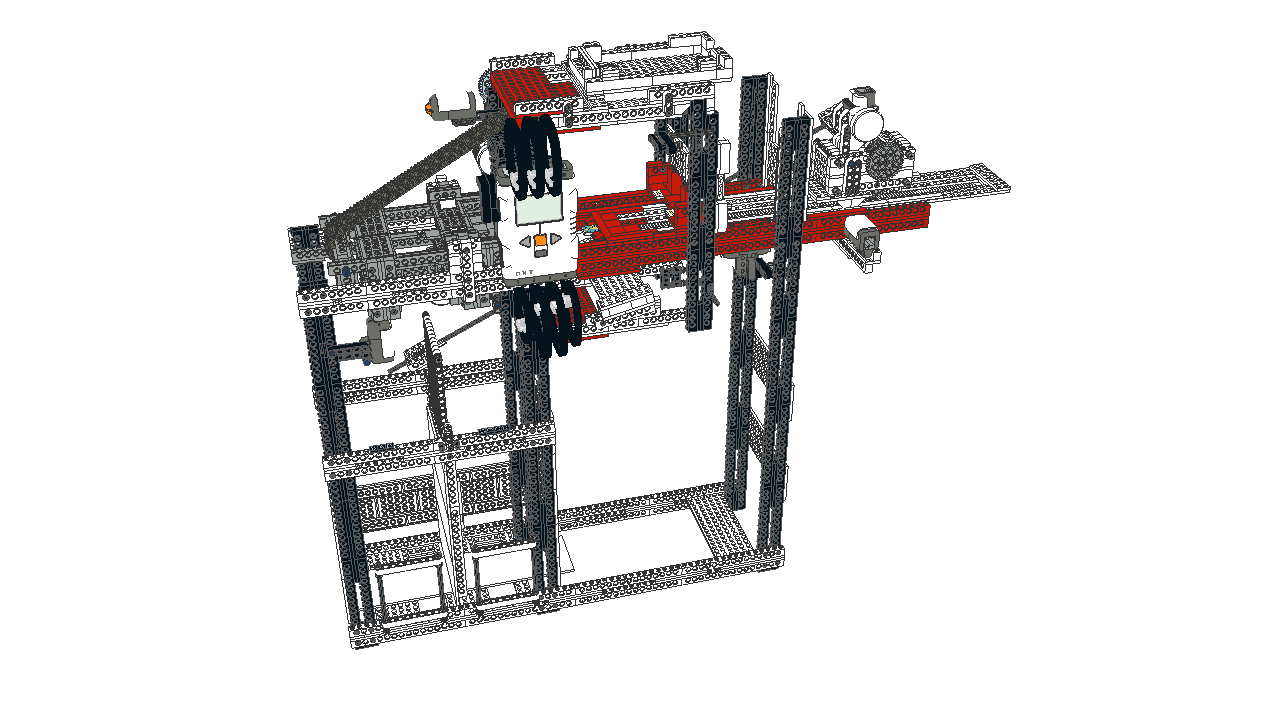

And naturally, I updated the model with the changes:

The general theme for the Mark II was to rebuild the machine with a cleaner construction, reasonable colors, and reduced part count. The general theme for the Mark III was to improve the reliability of the machine so it could process more disks with less baby-sitting.

All told, I had 1196 floppy disks. If you stack them carefully, they'll fit in a pair of bankers boxes.

And with that, I'm done. No Mark IV. For real, this time. I hope.

Previously: the Mark II

Attachments (3)

-

floppy-machine-mark3.jpg

(477.6 KB) -

added by retracile 10 years ago.

floppy machine mark iii

-

box-o-disks.jpg

(373.5 KB) -

added by retracile 10 years ago.

boxes of disks

-

floppy-machine-colorized.png

(77.1 KB) -

added by retracile 10 years ago.

floppy machine mark iii model

Download all attachments as: .zip

rss

rss

Comments

No comments.