Lining a Truck Toolbox

I bought a toolbox for my truck, but before I loaded it up with tools, I wanted to take steps to increase its expected serviceable life. One of the tools I carry is a hydraulic floor jack. This thing is heavy, and has a tendency to slide around. I didn't want it (and the other heavy, sliding-prone items it shares the box with) to hammer on the box. I grabbed some plywood I happened to have, and cut a section to fit the floor of the toolbox to protect the bottom. That left about 8-9" of plywood of the same length, so I cut that in half to make two ~4"-wide pieces. I nailed some scrap 2-by material to that to create a slot for end-caps, and made end-caps from some other scrap plywood I had lying around.

Each corner looks like this,

With the ends like this.

The end-caps hold the long walls vertical, and the 2-by bits nailed to the long walls keep the end-caps where they're supposed to be. So everything stays put, but it can all be disassembled and removed.

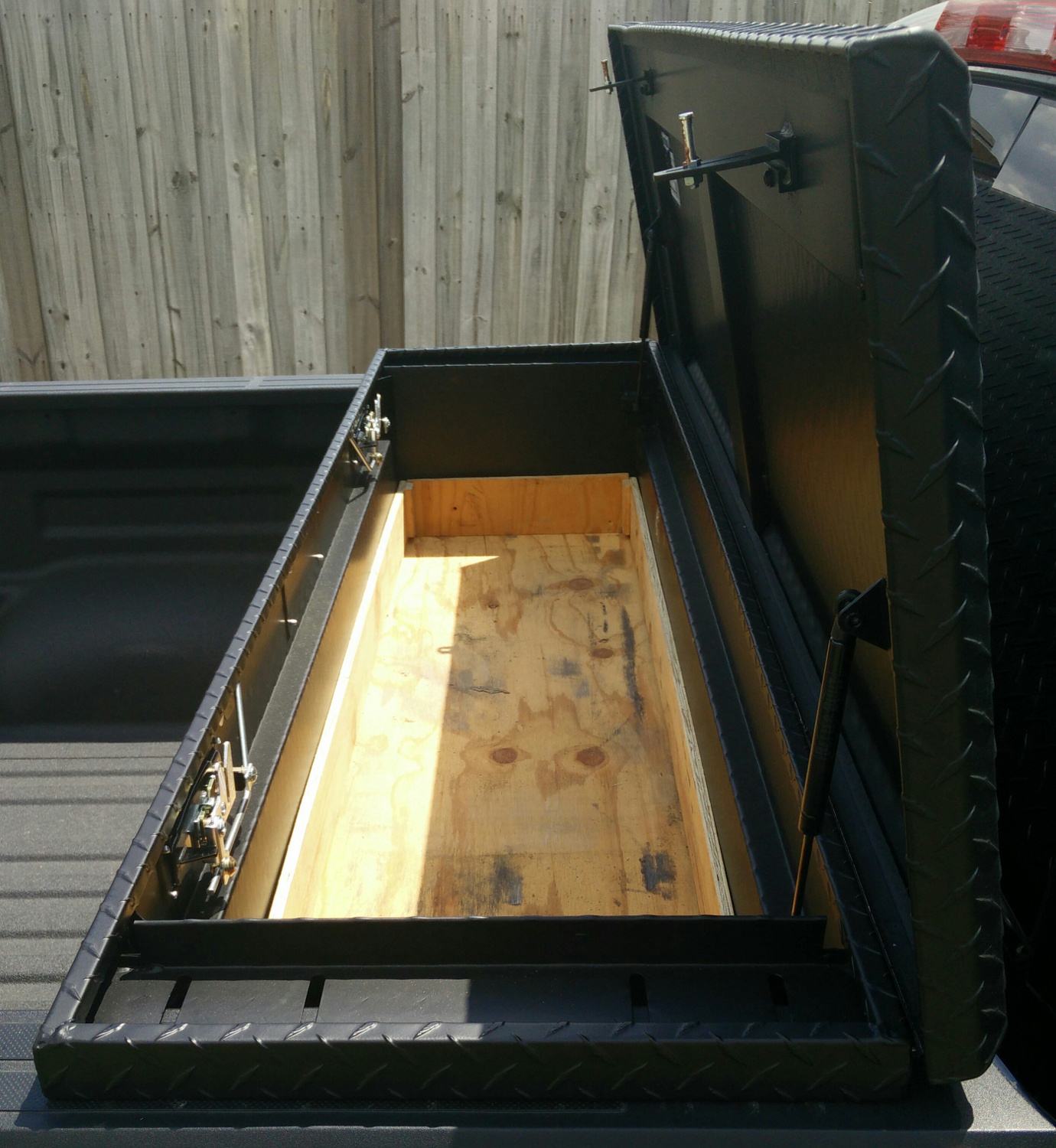

The end result looked like this:

Since the toolbox has seen a bit of actual use, you can see the dark gray places on the right half where the hydraulic floor jack's metal wheels have been sitting and sliding around. If you decide to build something like this, I'd recommend building the walls the full height on the inside of the toolbox; I noticed some scrapes where other tools have been rubbing on the inside walls. But for something thrown together quickly with materials already on hand, I'm satisfied with the result.

Making Stake Pocket Anchors

I bought a toolbox for my pickup truck, and needed to mount it to the bed rails securely. Using some J-hooks to bolt it to the metal inside the stake pockets did not work well enough; the loaded toolbox shifted from side to side while driving, scraping up the bed rail covers in the process. I needed a more secure mounting option for the toolbox that did not require drilling holes in my truck, and if I could avoid drilling holes in the toolbox, even better. Oh, and I needed to get it done immediately to avoid additional damage. While Magnum Manufacturing offers the stake pocket tie downs they use for their headache racks, I needed to solve the problem immediately, not wait for a well-made product to arrive.

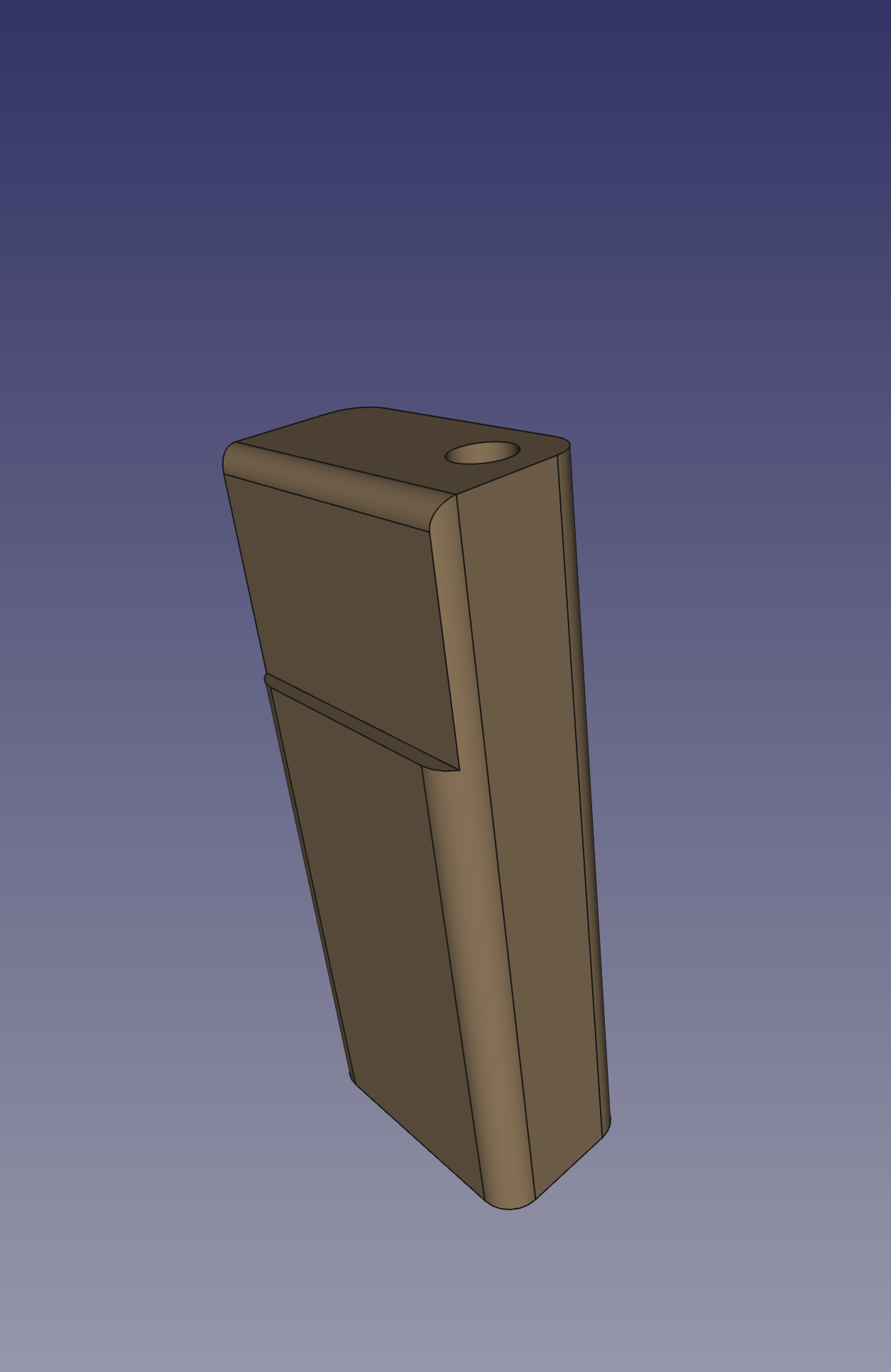

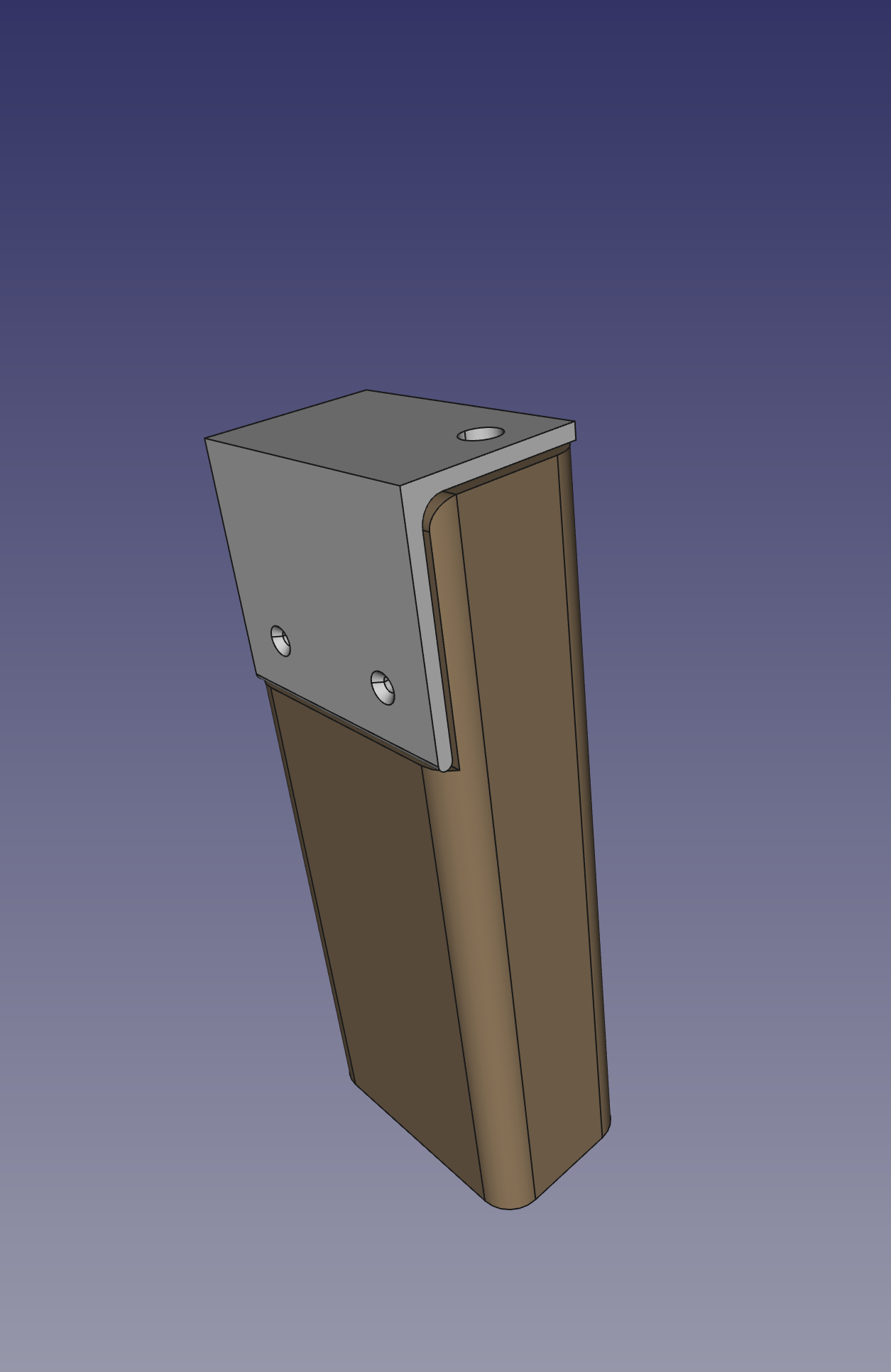

The concept is to have an assembly that fits into the stake pocket which I can bolt onto from the top, and fasten from the side. My solution was to cut some scrap 2x4 down to fill the stake pocket, and cut out space for a bracket, and a recess for the bolt.

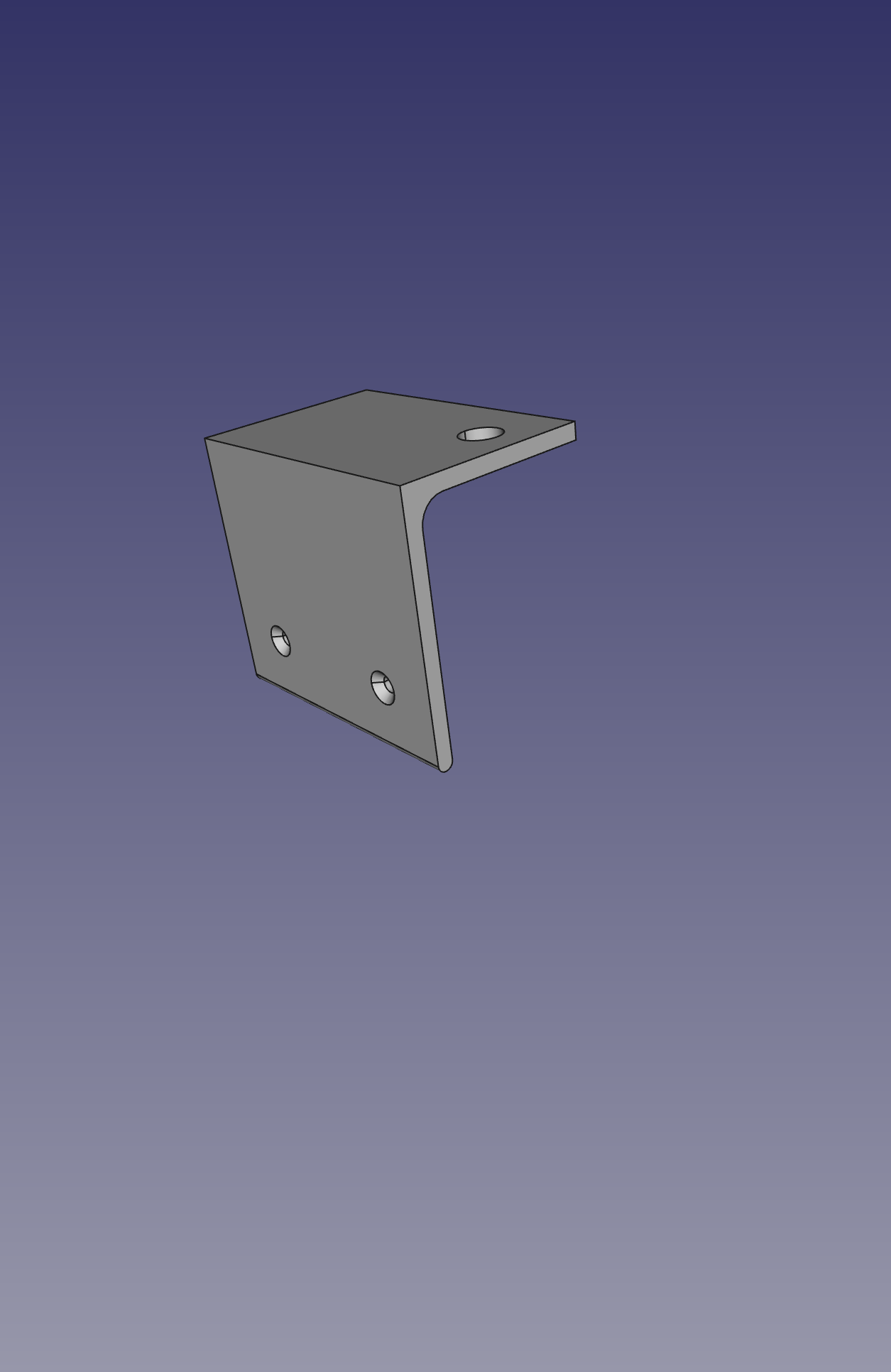

I fabricated the bracket from 1/8"-thick 2x2" angle iron; cutting it to size, drilling counter-sunk holes for the screws, and tapping a hole for a bolt on top.

I drilled pilot holes in the wood block and assembled the anchors with exterior wood screws:

Given that I was in a hurry and making it up as I went along, the actual anchors looked a bit more like this:

I dropped the anchors into the stake pockets and marked the location of the hole inside the truck bed, then drilled a pilot hole in the center of that.

Installing the anchors in the truck meant dropping the anchor in place

and securing it with an exterior wood screw and fender washer.

From there, it was a matter of lining up the toolbox slot with the bolt hole

and bolting it down.

Now, the toolbox is much more solidly anchored to the truck.

rss

rss