Heat-set threaded insert tooling box lid

I recently discovered heat-set threaded inserts. These little bits of brass provide a way to use bolts in 3D-printed plastic parts.

The idea is that you create a plastic part with a slightly-undersized hole where the insert will go, and then using a soldering iron with a specialized tip, you heat the insert, which softens the plastic enough that you can press it into the part. Once the plastic cools, the insert is firmly embedded in the part. The inserts have internal threads which a machine screw / bolt can be screwed into. They have sharp teeth features at opposing angles on the outside, so they remain firmly embedded in the part and can't themselves unscrew.

I bought a set of soldering iron tips for this purpose from Virtjoule (via Amazon). The set of brass tips came in a plastic tray which had obviously been 3D-printed.

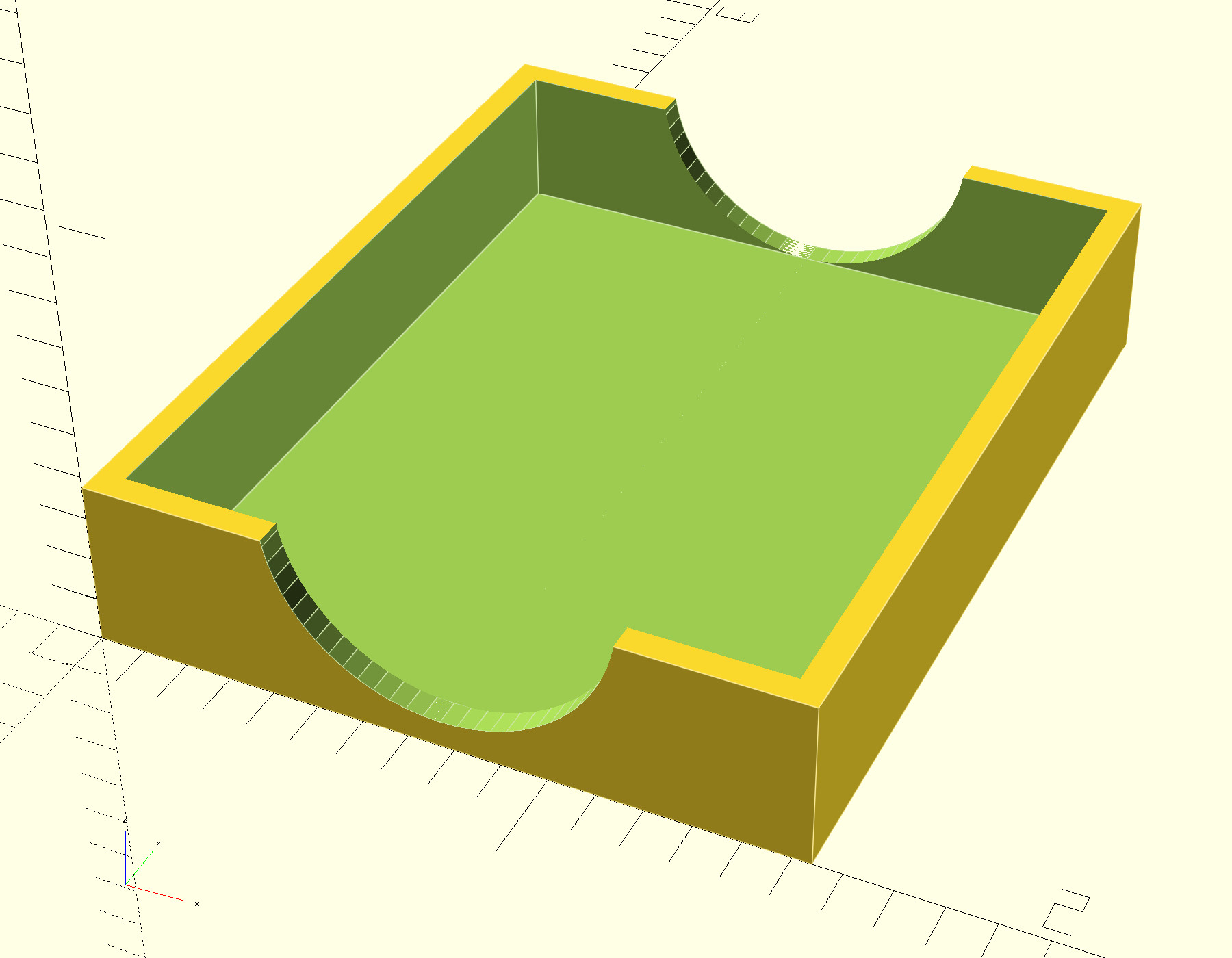

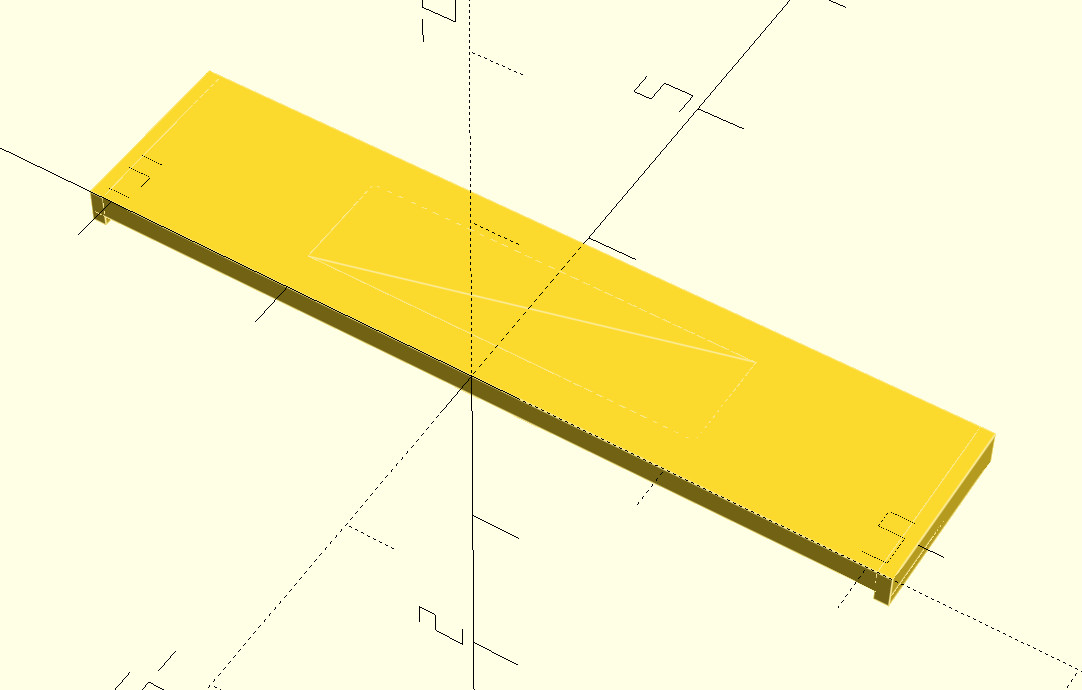

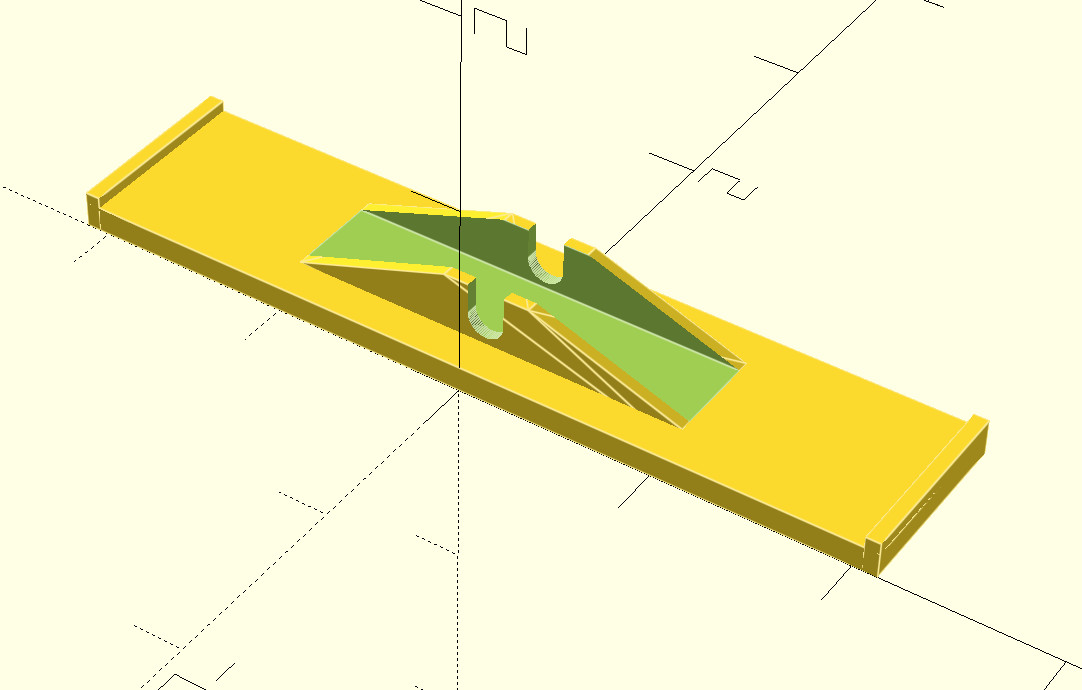

But there was no lid for the tray. So I threw together a 3D model of a lid for it (OpenSCAD, STL)

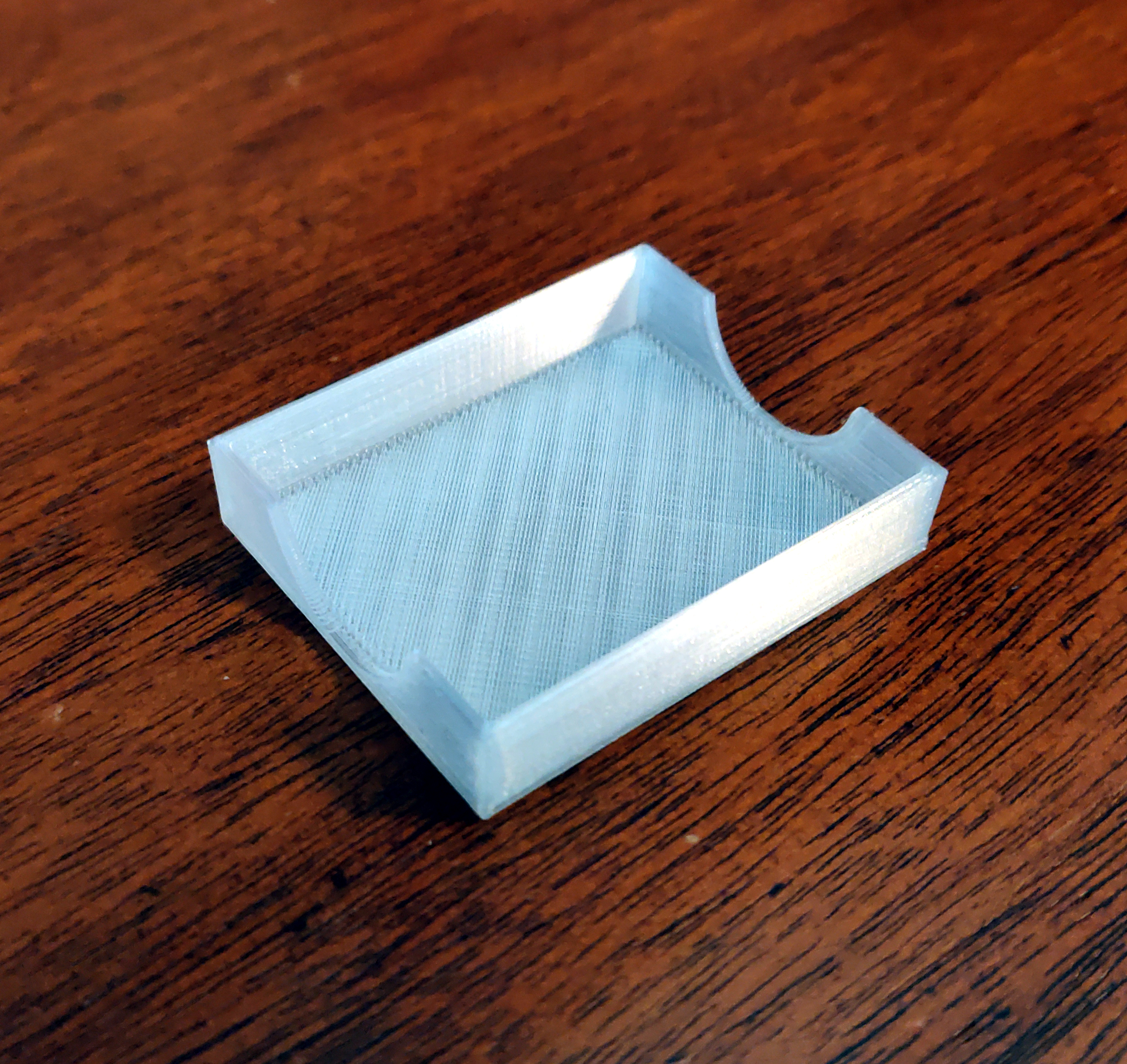

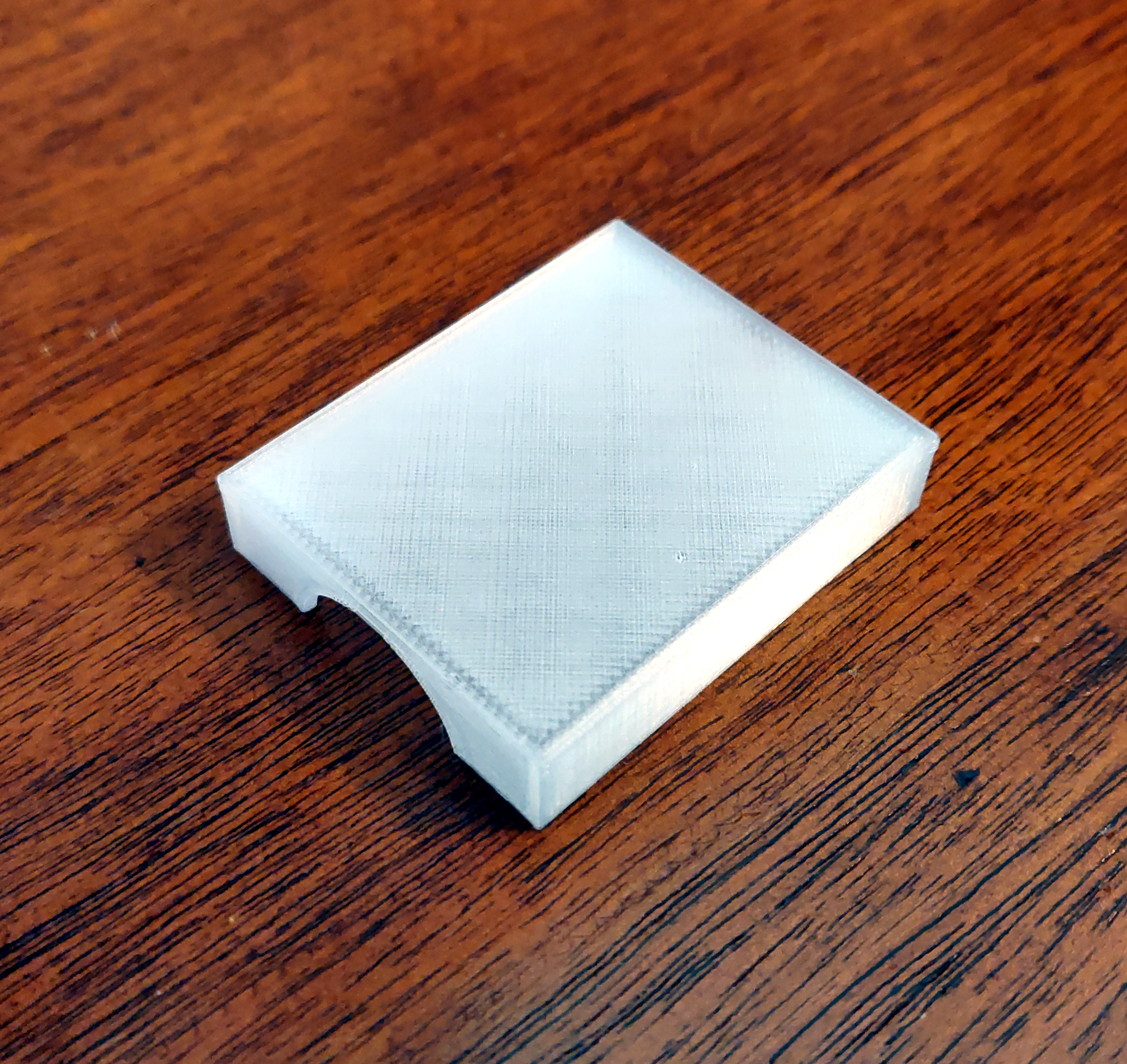

and printed it in "transparent" PLA.

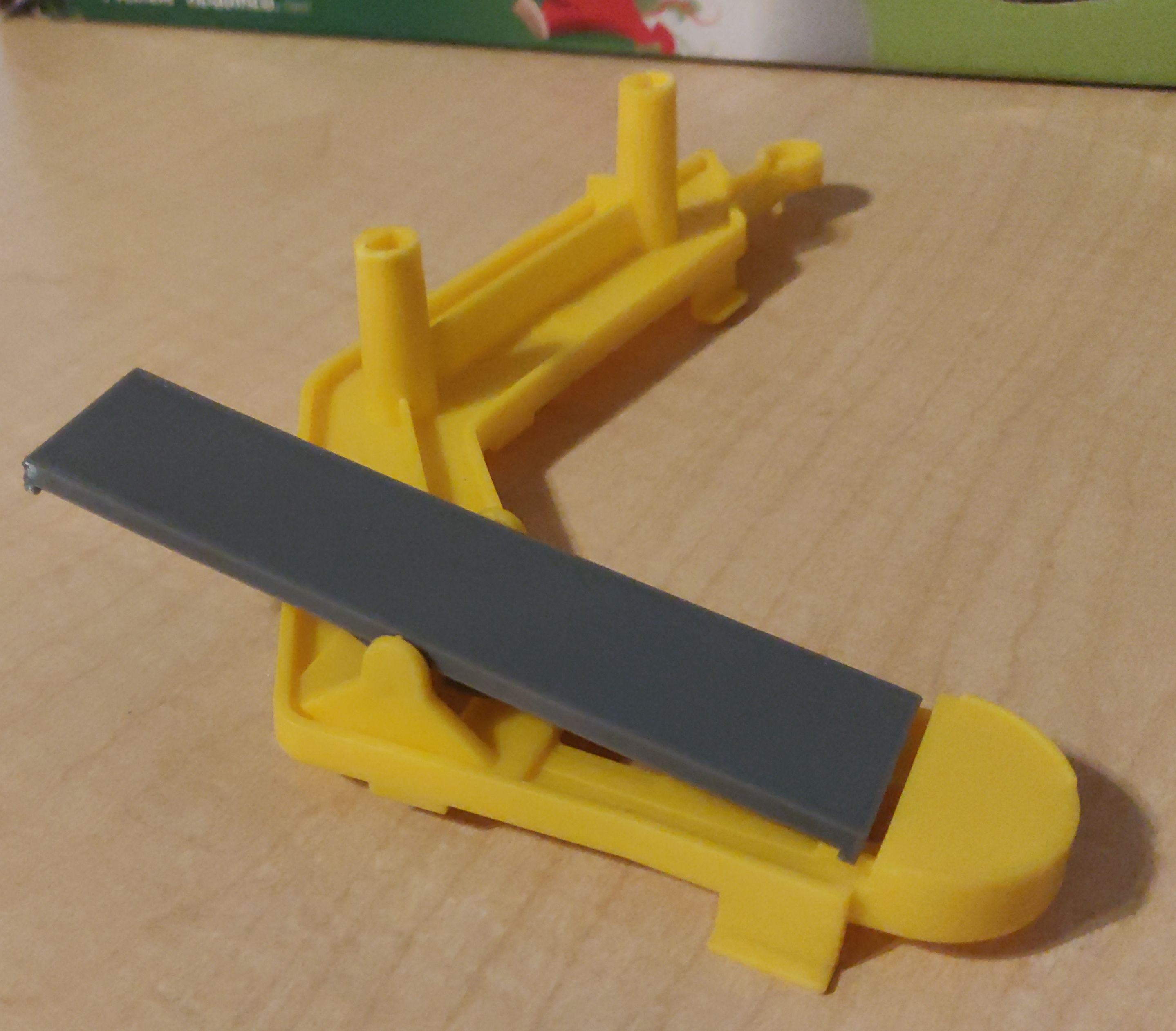

That fits nicely and helps to keep the set of tips together:

Being able to quickly create a lid for a box is not something I had anticipated doing with a 3D printer, but in retrospect, it's an amazingly obvious application.

And then there's the intriguing aspect that it's useful to a business creating packaging for a specialty product. In this case, the US-based company is in a business where they are applying 3D-printed parts, and are selling a tool they themselves created and use. So they've found an additional use of infrastructure they already had, and a market for a product they had created for their own use. I think that's really neat.

Mouse Trap replacement seesaw

There are some tools you figure will be useful, but it is difficult to really justify investing in them before you have them. And then you get it anyway, and discover how much more useful it is than you envisioned. Getting a 3D printer was that sort of experience for me; I knew I'd find it useful, but I hadn't realized just how useful. Using OpenSCAD and some calipers, I have managed to create replacement parts or useful gizmos that would not have occurred to me prior to owning a 3D printer.

Here is just one example.

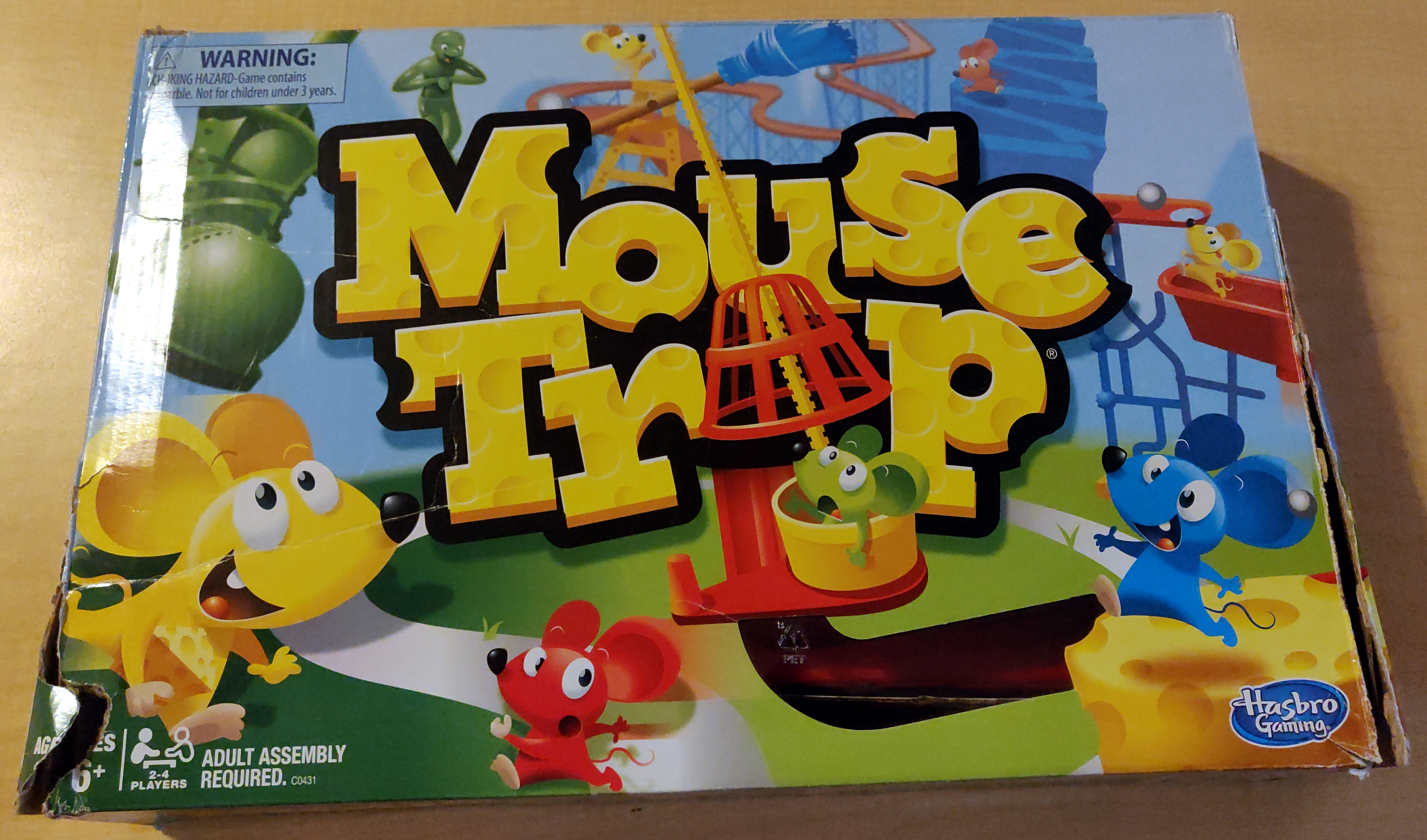

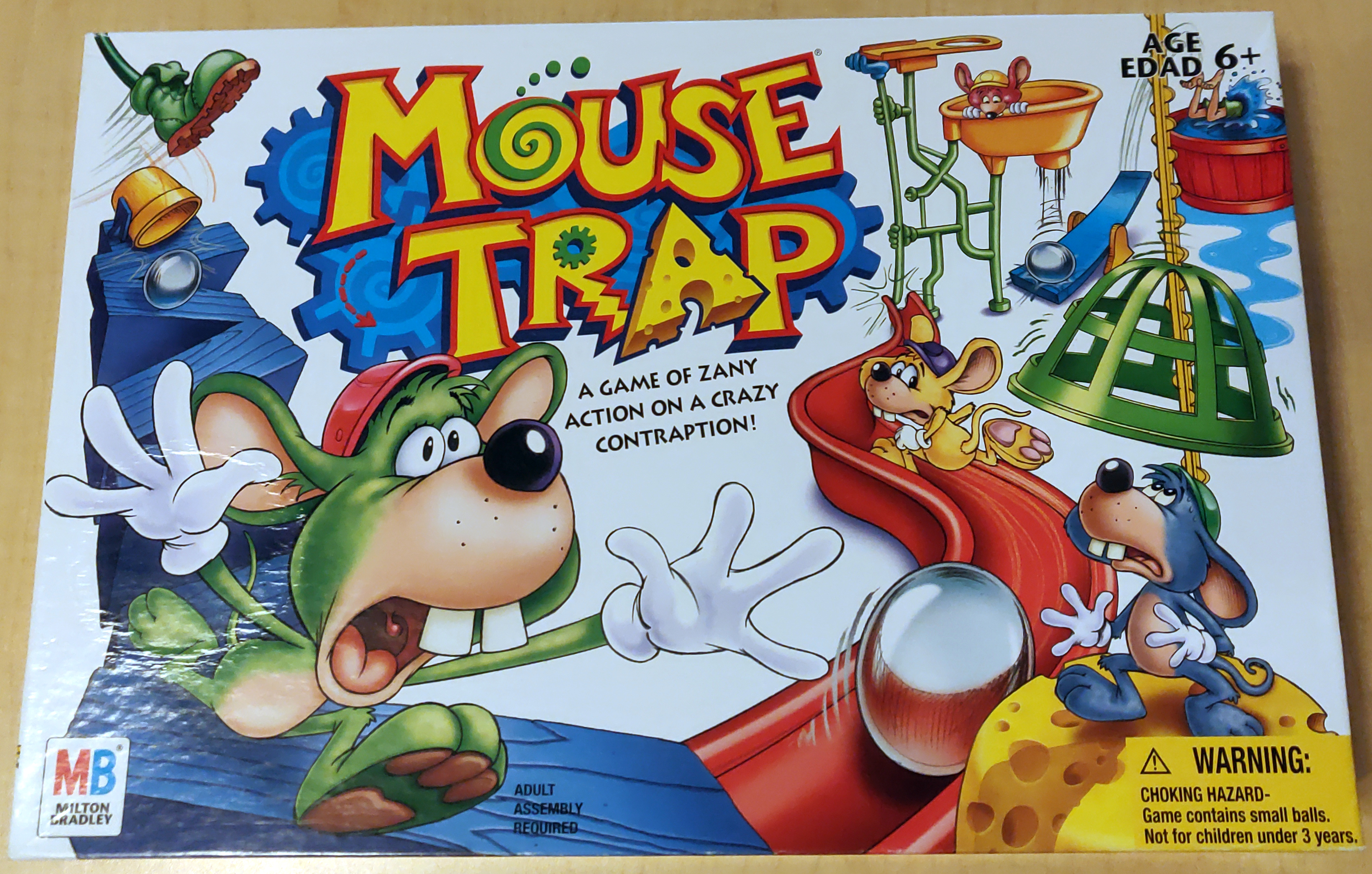

A friend of my wife had Mouse Trap, a kids' board game built around a Rube Goldberg contraption.

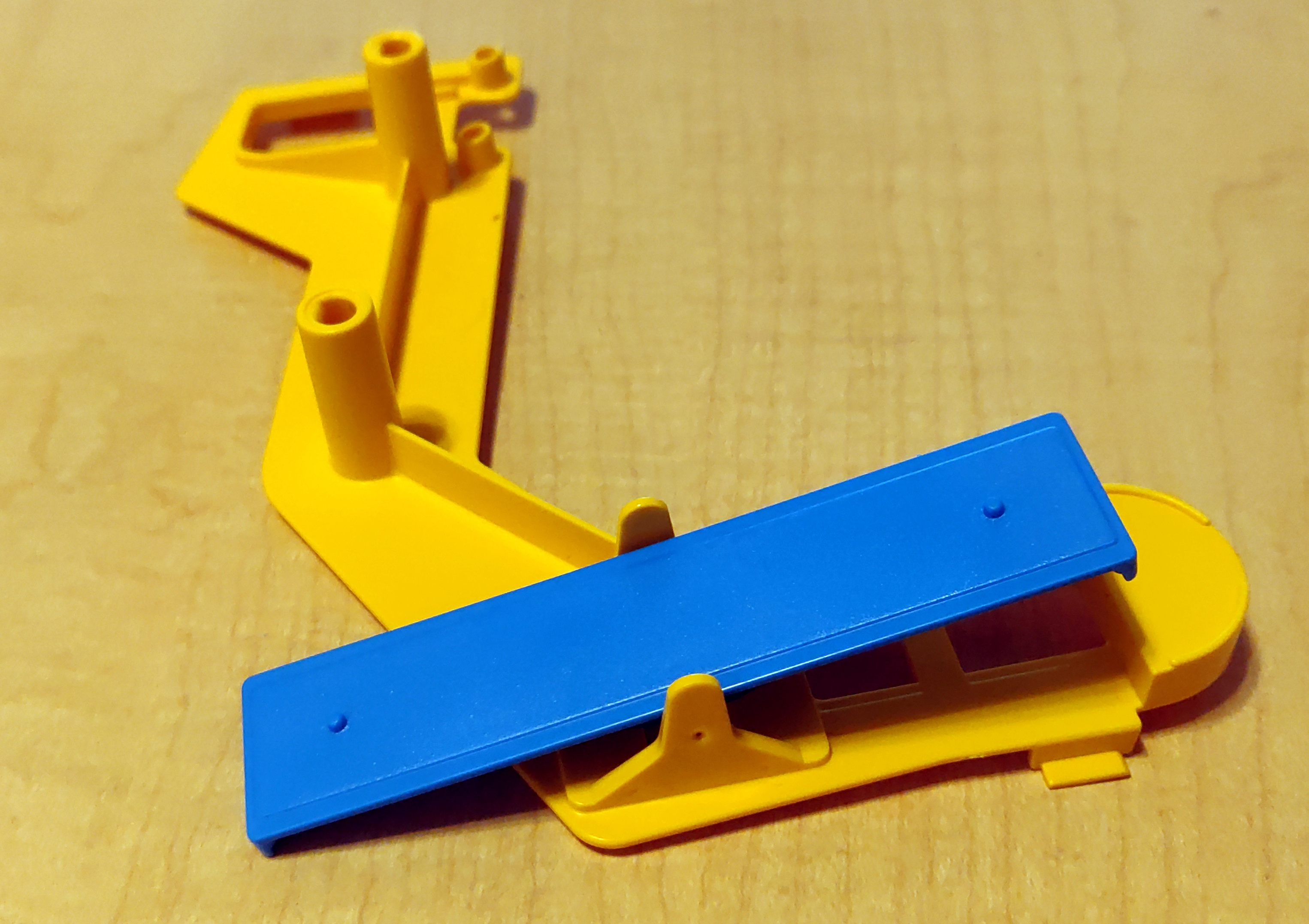

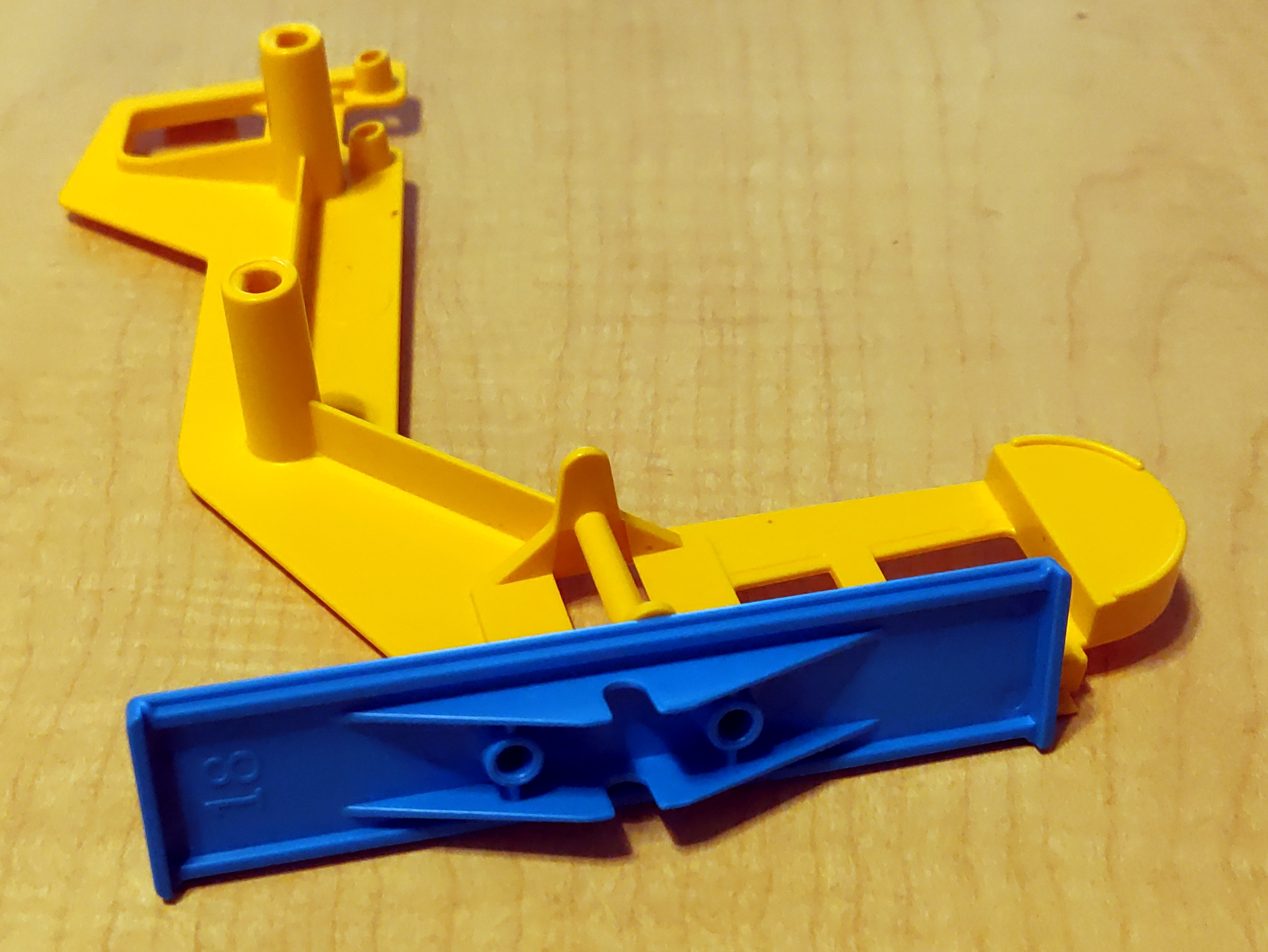

Unfortunately, she had lost the seesaw piece, which meant that the contraption could not work.

As it so happened, we also had the game, though it did have some differences.

The seesaw from our game still worked with hers.

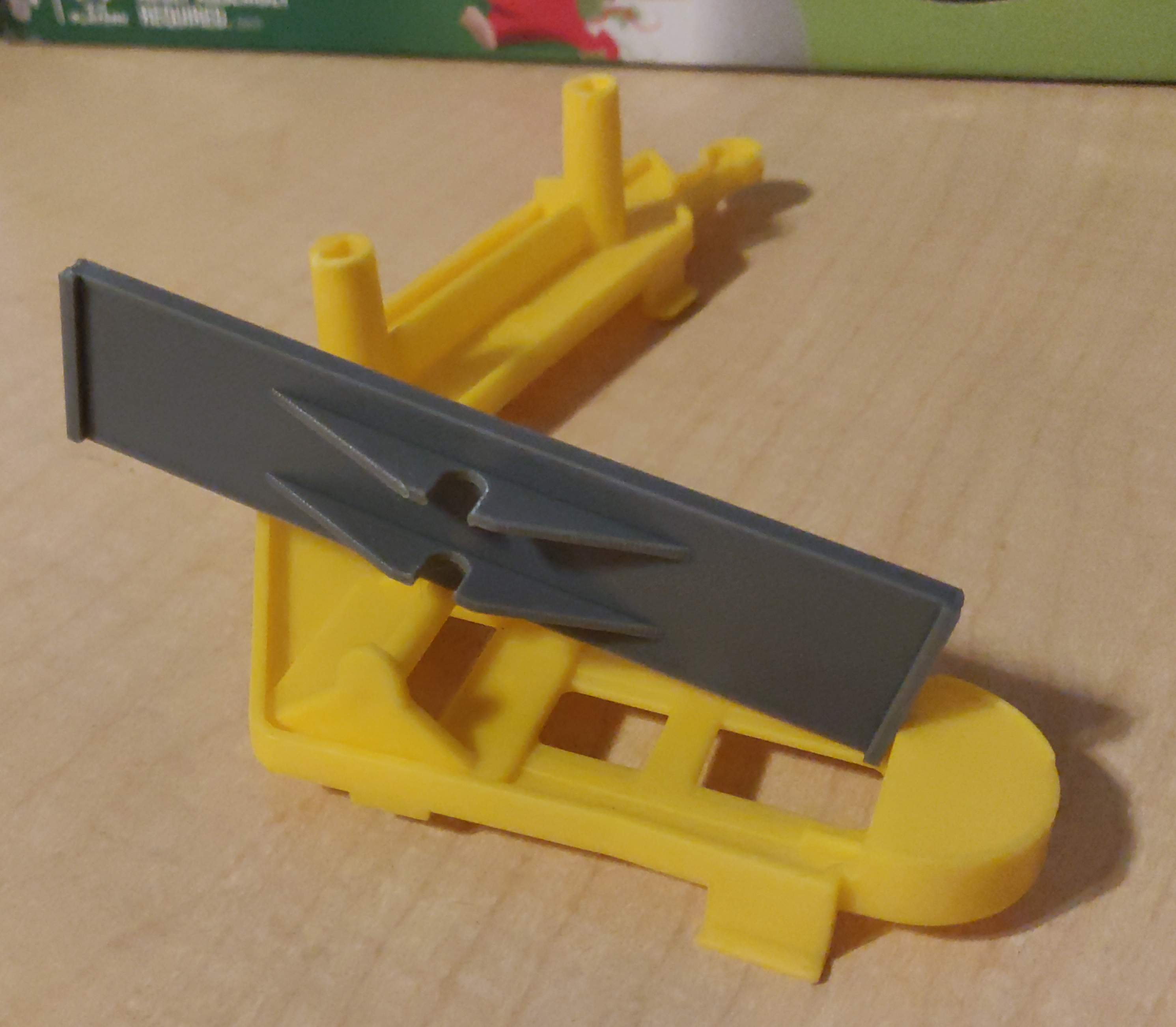

So I grabbed my calipers, and threw together a quick approximation of our seesaw in OpenSCAD,

and printed it out.

The resulting seesaw, though not as brightly colored as the rest of the game, did work, and fixed her game.

If you want to print your own, here are the OpenSCAD model and the STL.

rss

rss