Lego and aluminum phone camera tripod mount

For a family project, we needed a way to take pictures with the stability of a tripod. The best camera we own happens to be the one in a OnePlus 6 cellphone. We have a collapsible tripod with a standard mounting plate and bolt.

Those don't exactly attach to each other.

Ok, so how can we approach this? Well, the tripod has a 1/4" 20tpi captured bolt. So we need something rigid for it to screw into. I can drill and tap some aluminum to meet that interface. For holding the OnePlus 6, a frame built from Lego could work.

So all we need then is something that can bolt onto the tripod, and to which we can attach Lego pieces.

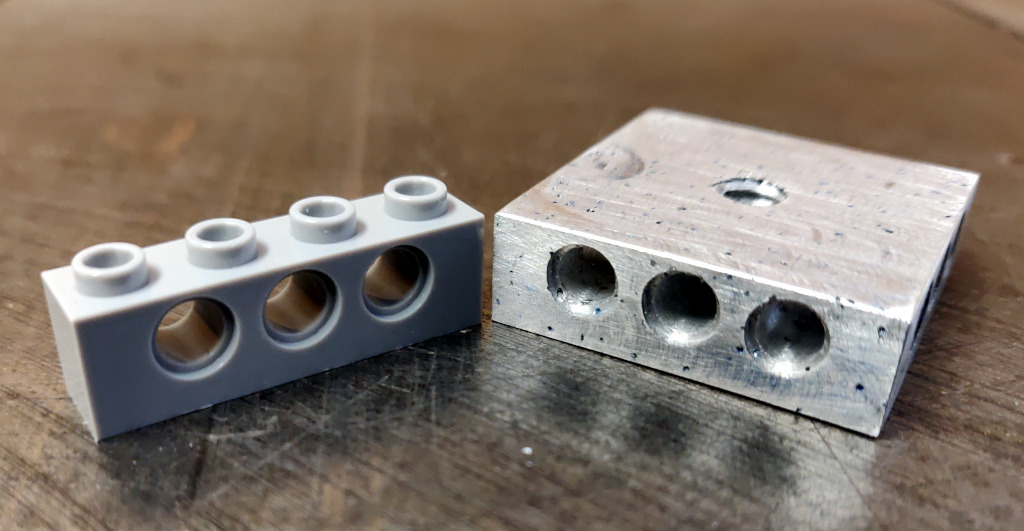

Studs look challenging to machine, and I expect they would be extremely finicky to get machined precisely enough to give the right amount of "clutch". And might be prone to damaging bricks, which we want to avoid. An easier approach is to drill holes compatible with Lego Technic pins.

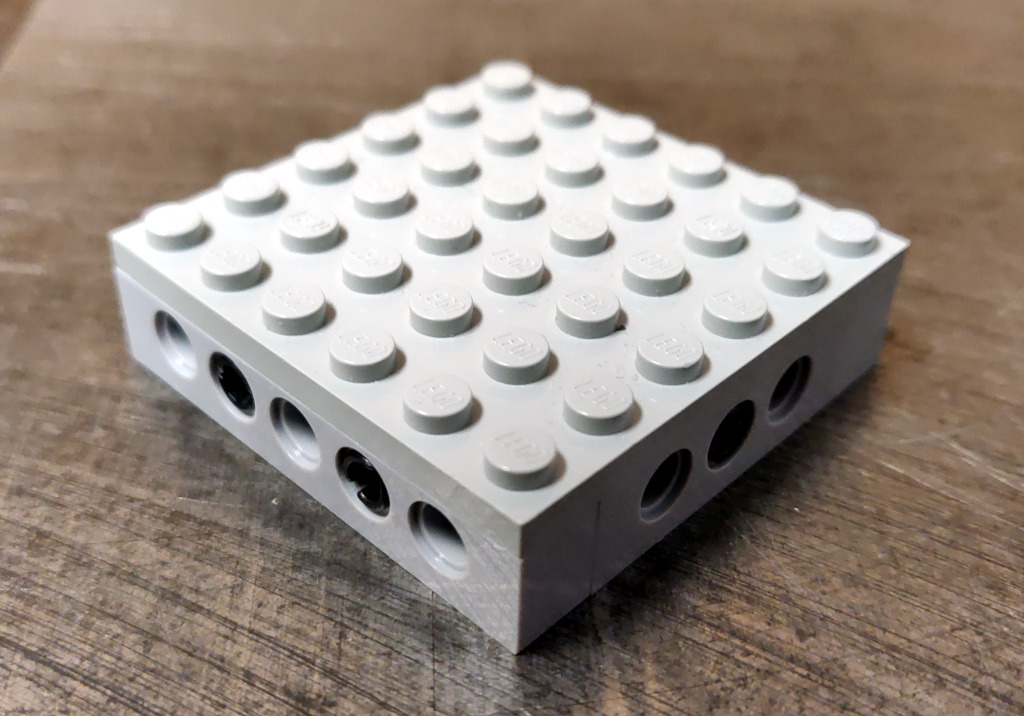

The tripod attachment plate is roughly 4 studs by 6 studs in size. So a 4x4 brick with a 1/4" 20-tpi hole in the center, with no studs, and with Technic pin holes around the edge should give us a very versatile base from which to work.

For material, I started from an aluminum ingot I had cast from cans, and machined that using my CNC mill (a Grizzly G8689 mini-mill with a HeavyMetal CNC conversion kit).

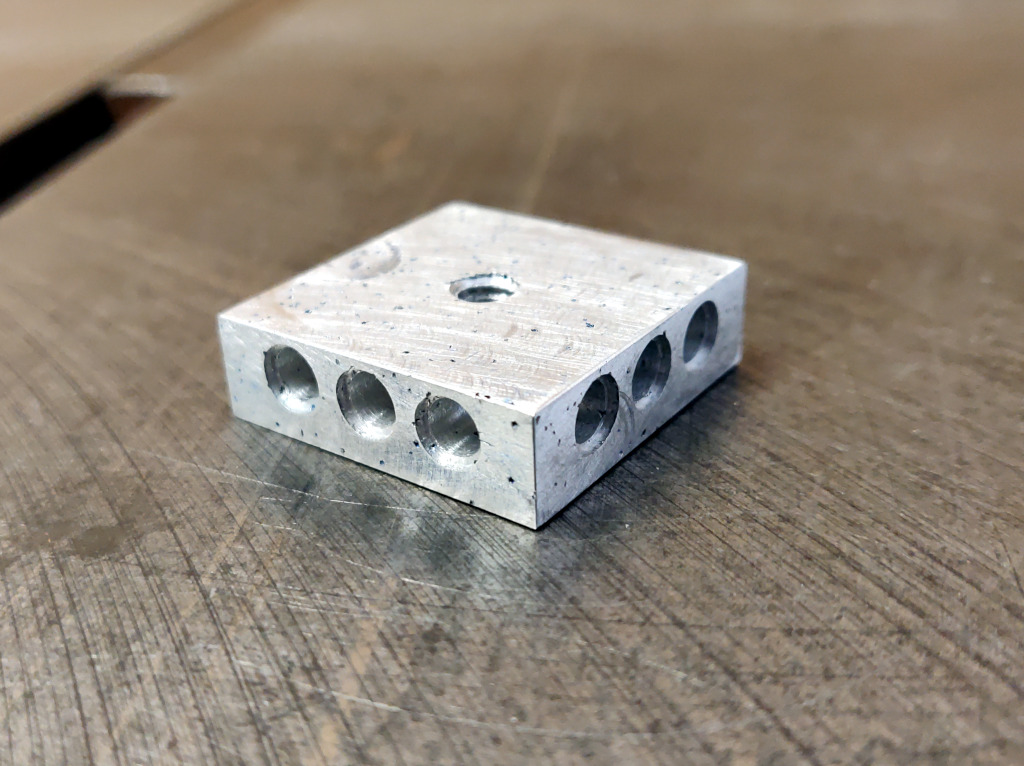

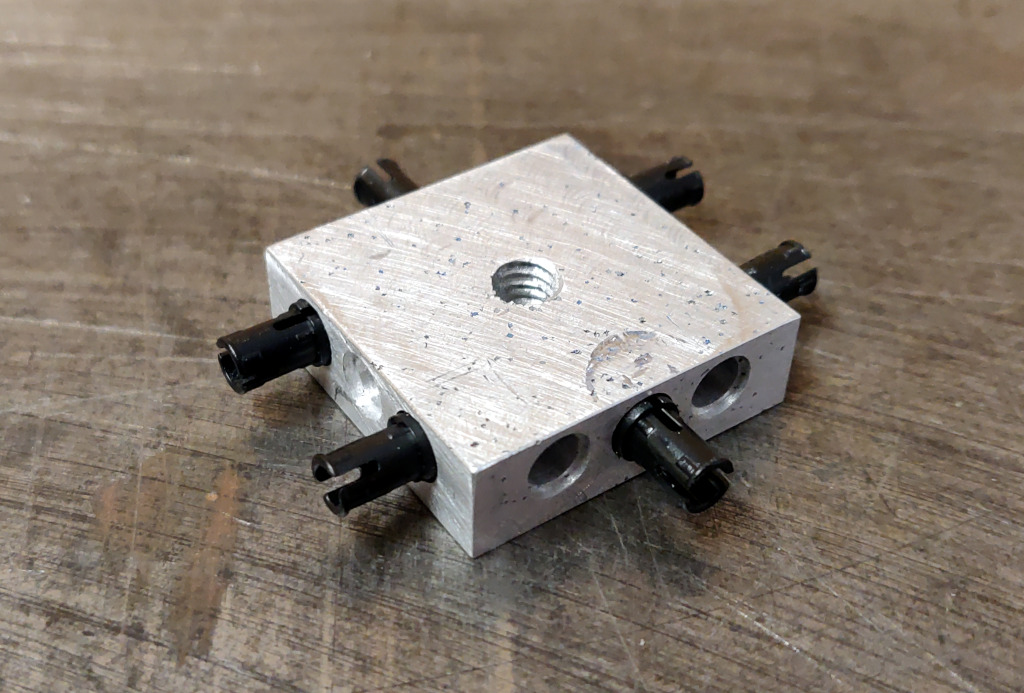

To start, I machined an aluminum block 1.254" x 1.254" x 0.380". (Ok, fine, the actual part was off by 2 thou, but it was close enough for the task at hand.) Then I machined 3 Technic pin holes on each of the 4 sides of the part. That included the shoulder around the top of each hole. I used an 1/8" endmill, and machined the outer ring, then the main hole within that. For each of those operations, I helixed down to cut the body of the hole, then cut the bottom circle to get a flat bottom. I don't have the g-code I actually used handy, but this gcode file gives the basic idea. Of note, the two Technic pin holes at each corner overlap partially within the part, so only one Technic hole at each corner can be used at a time. I then drilled a 13/64" hole through the center of the square face of the part, and threaded the hole with a 1/4" 20-tpi tap.

(There are many readily-visible flaws in the part. The casting had a lot of porosity, the edge of the tapped hole is rough, and there are some ugly machining marks on part of it. That said, they have not impaired its functionality.)

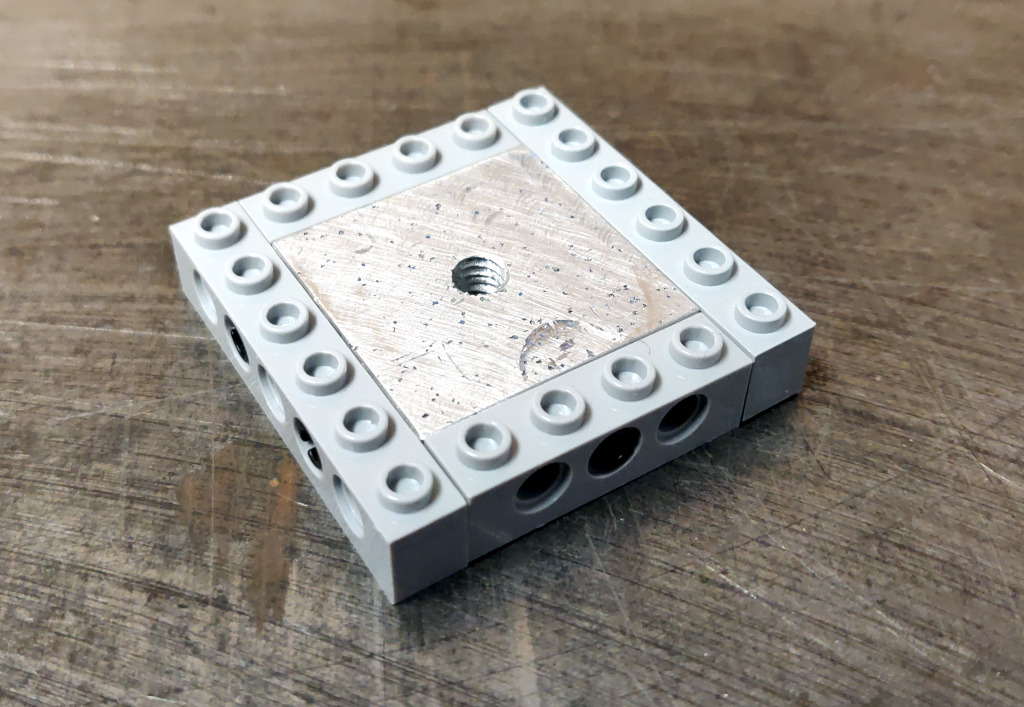

Once I verified that the part accepted Technic pins, and screwed down solidly on the tripod, I wrapped the part in Technic bricks and slapped a 6x6 plate on top of it. That gets us a Lego-compatible tripod.

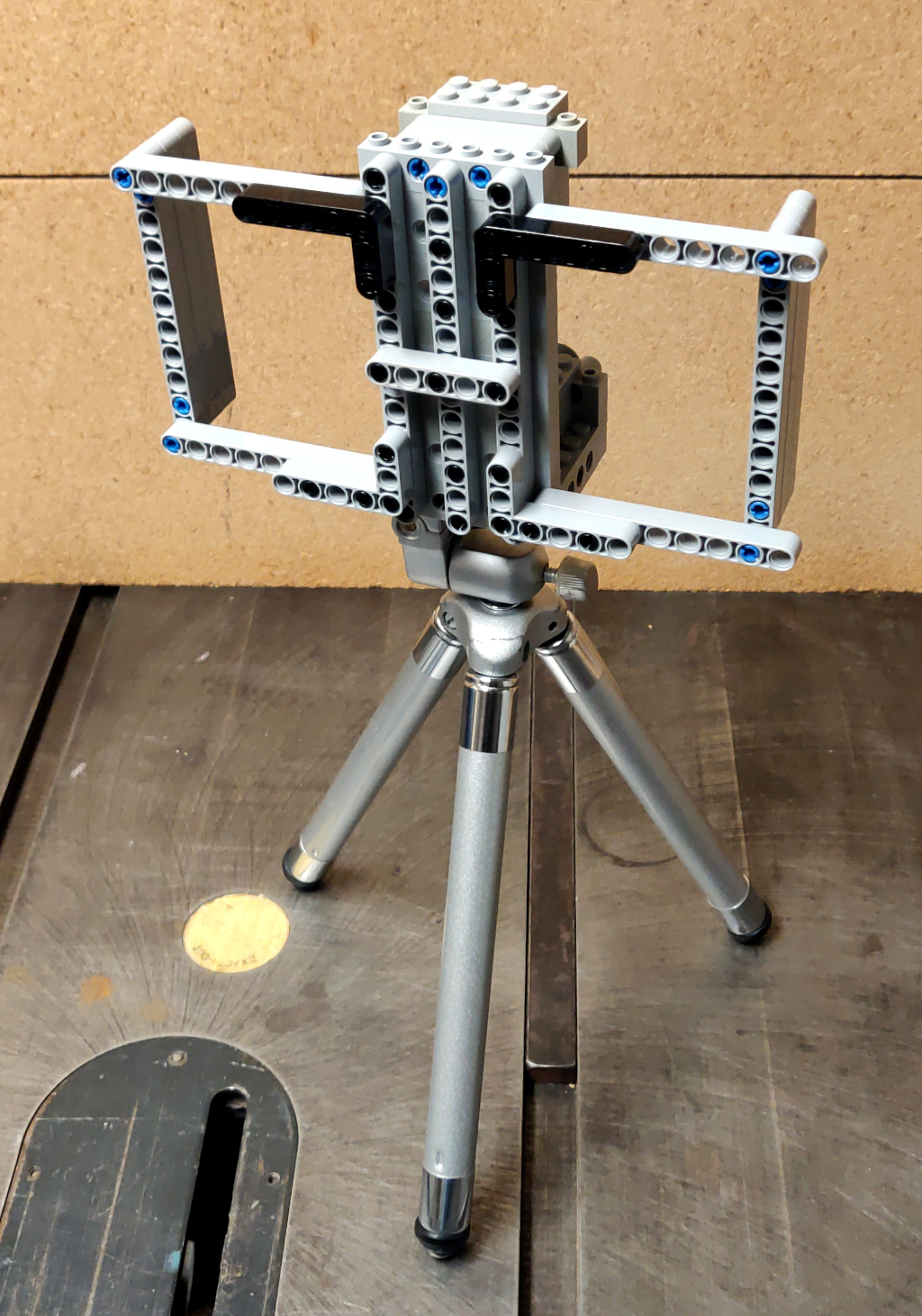

I then handed the contraption and a OnePlus 6 to my oldest son, Samuel, with directions to design and build a way to mount the phone on the tripod.

In short order, he came back with this:

While there is room for refinement and optimizing the part count, this thing is very solidly built and did the job well.

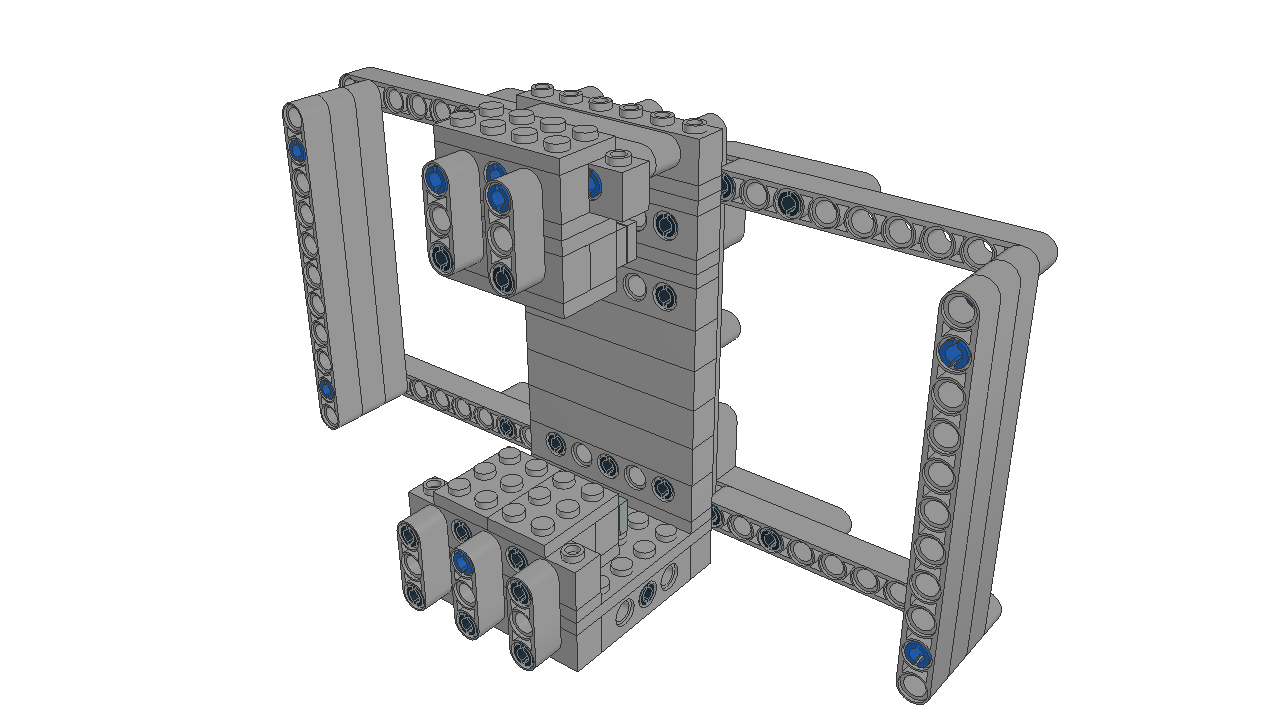

Using LeoCAD, I modeled the Lego portion of the contraption,

And I created build instructions using LPub3D for anyone looking to build their own.

Based on the success of this, I expect that the next time I need to interface between Lego and "the real world", I will use the same 4x4 Technic-compatible brick design and drill-and-tap holes to suit the need.

rss

rss